Start saving today

Whether you want to save on energy or avoid maintenance, we can show you how our smart monitoring solution will benefit your plant. Don’t wait any longer and start saving on time and costs right away.

Request a demoFor small and medium-sized industrial facilities, energy data has often been a matter of compromise. Our electricity sensors have made it possible to track consumption patterns, uncover inefficiencies, and reveal where savings could be found. Yet there has always been a gap when it comes to deeper insight.

Billing disputes, hidden costs caused by poor power factor, and the need to diagnose performance at the machine level all demand more accurate and continuous measurement. Until now, these capabilities were either inaccessible, prohibitively expensive, or simply too complex for SMEs to adopt.

The new Sensorfact Power Meter was created to change this reality.

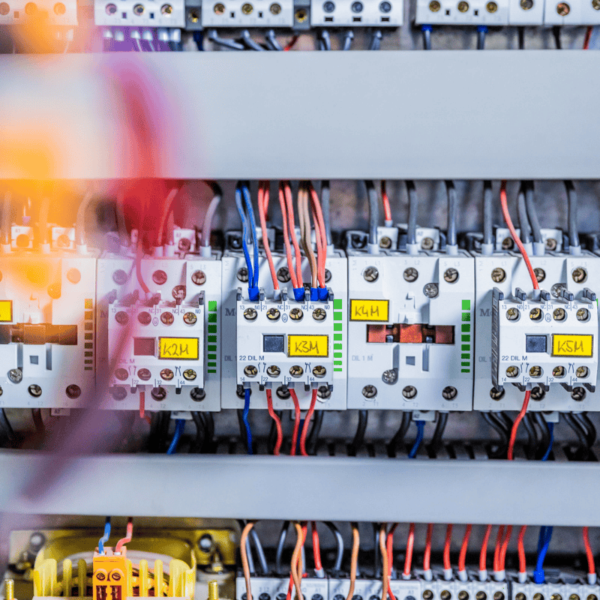

Electricity sensors are excellent tools for spotting consumption trends. They measure current with clamp-on technology and, based on fixed voltage and assumed power factor inputs, estimate consumption. This is more than enough for uncovering behavioral patterns and spotting potential savings.

But when precise values are needed — for billing validation, regulatory reporting, or diagnosing inefficiencies — assumptions are not enough. For example:

In other words, basic sensors highlight where to look, but they cannot provide the complete picture. That’s where the Power Meter comes in.

To understand why cos phi matters, it helps to look at how energy is structured. The electricity consumed by a system has two components:

The combination of the two is called apparent power (kVA). The power factor, or cos phi, is the ratio of active power to apparent power. A power factor close to 1 means energy is being used efficiently. A low power factor means a facility is drawing more energy than it actually uses — and paying for the waste.

Utilities often penalize facilities with poor power factors, and even when penalties aren’t applied, the consequences are real: overheating machines, reduced lifespan of equipment, and increased operational costs.

The Sensorfact Power Meter provides continuous visibility into cos phi, allowing energy managers to see exactly how their facility performs throughout the day and at the machine level.

Unlike standard electricity sensors, the Power Meter does not rely on assumptions. It directly measures both current and voltage, and from these values, it calculates cos phi dynamically.

This fundamental difference transforms the type of insight available:

The difference is best illustrated by comparison:

This evolution is what makes the Power Meter a breakthrough for SMEs.

Many facilities rely on audits or temporary analyzers to diagnose inefficiencies. While these provide valuable clues, they are ultimately limited to snapshots in time. Energy use, however, is not static. A machine that runs efficiently in the morning may suffer performance issues in the afternoon. Seasonal changes in production may introduce new inefficiencies.

Continuous monitoring bridges this gap. The Power Meter tracks performance 24/7, turning what was once a periodic investigation into an ongoing stream of intelligence.

This shift allows SMEs to:

Historically, this level of precision was only available through high-end analyzers designed for large enterprises. These devices were costly, complex to install, and often required specialist knowledge.

The Power Meter was designed differently. It brings the same depth of insight in a wireless, clamp-on device that can be installed in minutes — without interrupting production or requiring expensive electrical contractors. By removing these barriers, advanced monitoring is finally practical and affordable for SMEs.

The value of the Power Meter is not just in the data it provides, but in the decisions it enables. With accurate kWh readings, energy managers can dispute incorrect invoices. With continuous cos phi monitoring, they can avoid penalties and protect their equipment. With machine-level diagnostics, they can target investments where they will have the greatest ROI.

In short, the Power Meter transforms hidden energy waste into visible, measurable, and actionable savings.

Energy management has always been about more than tracking consumption. It’s about clarity, control, and confidence. With the Power Meter, SMEs now have access to the same kind of precision data that was once reserved for large corporations — delivered in a format that is simple, affordable, and tailored to their needs.

The blind spots are gone. The hidden costs are visible. And for the first time, SMEs have a tool that combines accuracy, accessibility, and actionable insight in one device.

Whether you want to save on energy or avoid maintenance, we can show you how our smart monitoring solution will benefit your plant. Don’t wait any longer and start saving on time and costs right away.

Request a demo